More info

Turn on English subtitles:

The Thor Elite reflux still is a lowered version of our Elite model, allowing you to obtain 96%+ pure product and flavored spirits. The height reduction is made possible by using a different type of head - a completely horizontal system called - because of its shape - Thor's Hammer. The operation of the column is identical to any other LM/OVM rectification column, as the change in orientation of the condenser from vertical to horizontal does not affect the ease of operation.

The column has a LM system (precision receiving valve in the head) for receiving flavored, grain, fruit, or aromatized spirits, and an VM system (with Liebig condenser) for obtaining pure alcohol >96%.

Due to the fact that the Thor head is chosen due to the height saving it is best to determine the height of the whole individually. We will adjust the height of the column to your room. The space you save will mean more room for packing or for adding a buffer. Simply select the desired height from the configurator menu on the right side of the product card (above the description).

Description of the systems used in the column:

1. VM system. Its operation is based on "sucking" saturated ethanol vapors from the packing and directing their flow through the valve to a simple Liebig cooler. The amount of vapor is regulated by a ball valve located in front of the cooler at the height of vapour intake, a few centimeters below the head.

2. The LM system is a liquid flow control. Reducing the amount of distillate received with a small valve, we change the amount of distillate returning to the packing. With this system, apart from very pure spirit, we can obtain flavored distillates, i.e. herbal, fruit, and grain distillates, such as plum brandy or whisky.

By opening the LM valve to the maximum, we obtain the same effect as in simple distillation, or pot-still. The column then works without reflux and the product is as it used to be - pot still is used for flavored distillates, where the straight distillation extracts the aroma of the raw materials. If flavored, fruit, and grain distillates will be an important part of your production, we recommend that you order an LM cooler and a parrot to check the strength of the receiving distillate as you go. This helps with receiving and makes it easier to work with flavored distillates.

The head is equipped with a sight glass for better interaction with the column. It allows us to see what is happening inside. Observation of the column flooding also translates into electricity savings (more precise power control) - seeing the moment of flooding we can reduce the power to heat the most efficiently. In addition, we can control whether the column is not affected by flooding which may affect performance.

Temperature measurement takes place in three places - at the bottom of the column, under the head, and in the tank. The kit includes our precision LCD thermometer with measurements to two decimal places. Better thermometers mean better control. This allows you to catch any temperature change in the column and gives you time to react. The repeatability of measurements allows you to draw conclusions from the subsequent processes and better learn about your column and the phenomena occurring in it - thanks to this when rectifying similar batches in succession, you can predict the quantities, times, speed of reception and the whole work goes much more efficiently and requires less attention from the operator.

The column is filled with spiral prismatic packing. The whole still acts as a catalyst, so there is no need to fill it with additional copper filling and waste valuable space for it. You can have a larger fill of good steel prismatic fill. The fill is partitioned to avoid spring clumping and increase efficiency.

The boiler is an insulated keg with a capacity of 30, 50 or 100 liters with heating elements- 2x2kW (30 and 50l) or 3x2kW (100l). Tanks heating time (13% mash, start temperature 24*C) is:

Keg 30l (27l liquid): 30 minutes (2x~2kW)

Keg 50l (47l of liquid): 52 minutes (2x~2kW)

Keg 100l (95l of liquid): 70 minutes (3x~2kW) or 55 minutes (4x~2kW)

The boiler has an additional 3/4" inlet (to connect e.g. pump), with the possibility to mount 2" or 4" Tri-Clamp inlet. Drain is a standard 3/4" valve with the possibility of enlarging to 1 or 2 inches.

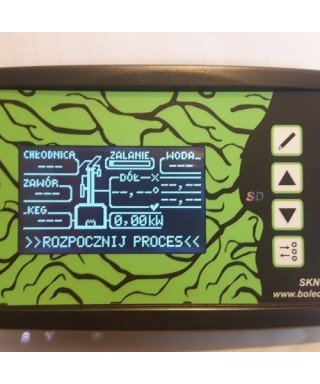

The still can be automated. It is possible to add a simple automation E-ARC or - for advanced users - SKN controller by Bolecki, which controls the entire process. SKN controller has the possibility of saving process logs on SD memory card and a possibility of a remote software update. It provides temperature measurement in 3 points and control of motor valve VM, two solenoid valves (water and foreshots), as well as heating elements. By choosing the SKN controller from the drop-down lists of the configurator, you will get a set without unnecessary regulator and thermometers from the standard set - you will save over 300 PLN!

Accessories