Kategorie

Reflux stills

- Promotion

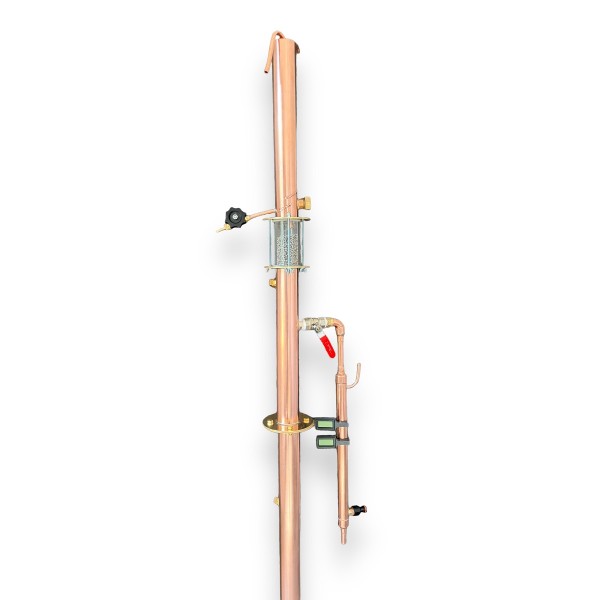

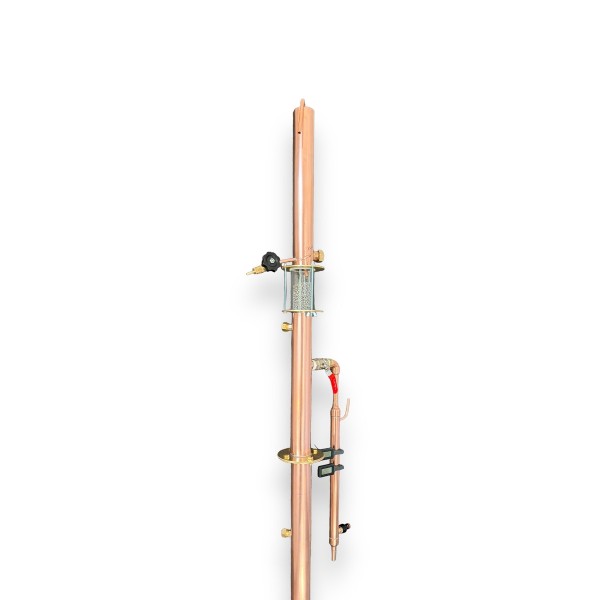

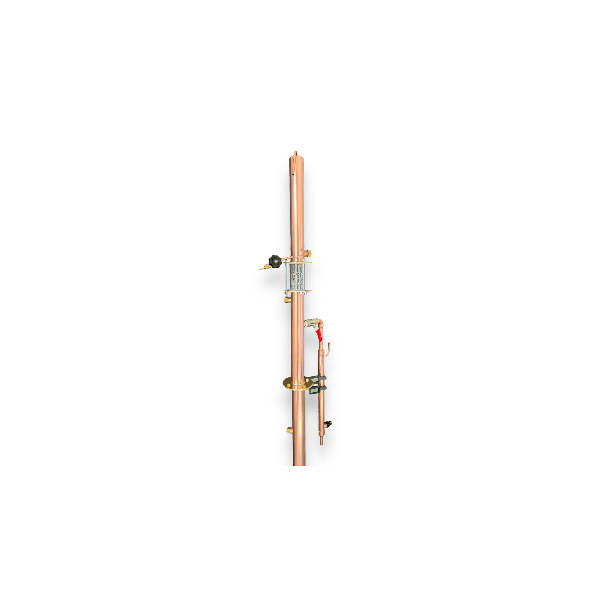

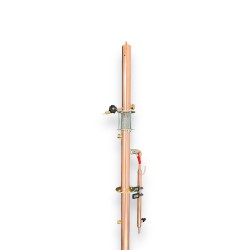

Premium LM/ VM reflux still

Worldwide delivery

Made in Poland

Our shipments are insured

About this product

Copper Premium LM/ VM still with sight glass, rubber insulated kettle with 4000W heating elements, Riegler precision valve (LM takeoff)and two LCD thermometers for making 96+ neutral as well as fruit brandies and grain spirits.

The Premium still is the most popular choice among beginners. It is a versatile column that allows you to effortlessly produce both flavorful and odorless, neutral, smooth spirits quickly and without any issues. With its precise LM valve and glass sight glass in the packing, you maintain complete control over the entire process.

The still is equipped with three distillate collection systems. The first system, LM with a precise valve in the head, is designed for flavorful distillates from fruits, wines, grains, and herbs. Thanks to the Riegler needle valve, you can achieve unprecedented precision in distillate collection. It has up to 7 full turns between the extreme positions, allowing for precise drop-by-drop collection or full opening.

Additionally, the Premium still features two independent side vapor collection systems: VM and its evolution, the Lowered VM (OVM) system. Both systems enable the production of neutral spirits with over 96% purity from start to finish, without any loss of strength or quality. The vapor collection systems consist of an outlet in the head (VM) or below the sight glass (OVM), a vapor path valve with a lever, and a final condenser. The innovative design of the condenser, equipped with water channels, allows it to be connected in series with the top condenser, ensuring that you only need to supply cooling water to one point of the entire still. The still can be cooled in a closed system and, unlike CM-type columns with "cold fingers," can be easily operated even with installations that do not provide constant pressure (e.g., those relying on a hydrophore or with a large number of water users connected to a single supply line).

The column is equipped with a sight glass under the head, which allows you to monitor the packing, flow from the head, and potential flooding of the column (in case of excessive heating). Flooding during the process is undesirable as it reduces the separation capacity of the column. With the included power regulator, you can adjust the heating to prevent flooding (rising liquid level). The practical adjustment of the appropriate power is described in the instructions and poses no difficulties. It is also presented in the video.

The still is paced with spiral prismatic packing (SPP) that maximize its separation capacity. This is the best available filling for rectification stills, being approximately 15 times more efficient than Raschig rings and twice as efficient as scrubber packing.

The height of the Premium set is as follows:

- Still alone: 170cm

- On a 30L keg: 210cm

- On a 50L keg: 230cm

- On a 100L keg: 245cm

The 30L keg boiler (also available in 50L or 100L) comes standard with two ~2kW low-density power (ULWD) heaters. This allows for boiling even thicker mashes, such as fruit wines. The tank has a 3/4" drain valve and a 3/4" fill port with a plug. You don't need to dismantle the column to empty the mash after the process.

The entire boiler is insulated with a rubber coating, reducing energy losses during heating and allowing for lower power consumption. The insulation also reduces the risk of burns from a heated boiler.

The still is mounted to the keg using a Tri-Clamp connection, secured with a special clamp that does not require screwing in the boiler. This is a secure connection, and the material of the clamp ensures long-term operation without the risk of wear or damage. A silicone gasket is used to seal the connection. Thanks to the Tri-Clamp connection, you can position the column in any orientation.

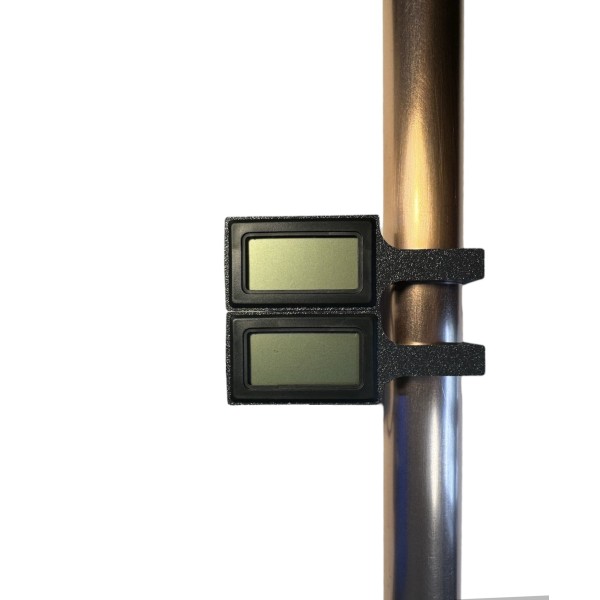

The set includes two thermometers with large-contrast displays, allowing you to maintain full control over the process. The LCD thermometers provide readings from the bottom of the column (for spirits) and below the head (for flavored distillates). In the options, you can choose a precise thermometer with DS probes that displays readings with a resolution of up to two decimal places.

Detailed instructions for operating the still are provided in the illustrated manual included with each unit. The column is straightforward to operate and poses no difficulties, even for customers who have not previously used a rectification column. In addition to equipment connection and operation diagrams, the instructions also cover necessary information for beginners, such as planning and preparing mashes and washes, advice on aging and storing distillates, as well as descriptions of useful tools and accessories for this new hobby.

The product obtained from the Premium still does not require activated carbon filtration.

The standard set includes:

- Insulated 30L tank with an additional 3/4" fill port with a plug and a 3/4" drain port with a valve, equipped with two ULWD heaters with a total power of ~4kW.

- Heater power regulator.

- Three copper still elements with SPP

- 1/4" LM Riegler collection valve.

- Sight glass elements.

- Gaskets and complete set of connection screws.

- Tri-Clamp clamp for connecting to the tank.

- Two LCD thermometers with a convenient thermometer holder

- Copper top condenser with PCV hose for connection to the VM/OVM condenser.

- VM/OVM end condenser with valve.

- Heater shields.

You are purchasing a complete set; you only need to connect water and electricity. For water supply, you can purchase a complete set of hoses and connectors available in various lengths. We recommend using silicone hoses for alcohol.

Options can be expanded by selecting items from the dropdown lists on the right side above the description. You can also purchase a range of accessories for the column available in our store, which can be found in the related products section below.

Standard configuration

- Stabilizing buffer

- Without buffer

- Diameter

- 54mm

- Heigh (without boiler)

- 170

- Boiler

- 30l

- Heating elements

- 2x2000W + power regulator

- ean13

- 5907222624050