CM, VM, LM, OLM, OVM - what do these abbreviations mean and how to understand them?

CM, VM, LM, OLM, OVM - what do these abbreviations mean and how to understand them?

These abbreviations refer to methods of collecting distillate in a rectification column. In simple distillation, the process is straightforward. There's a boiler, a vertical deflegmator (or not), and a condenser at the end, from which the final product is collected. This is how every pot still works, or a simple distiller. Oh, by the way, the deflegmator is that vertical tube above the boiler :)

However, rectification columns are a bit more complex. At the top of each rectification column, there's a top condenser. Alcohol vapors exit the boiler, pass through the column, and condense on this top condenser, from where they 'fall' back onto trays (in a plate column) or packing material (in a packed column) below. This phenomenon is called 'reflux'. The condensed vapors are reheated by 'fresh' vapors coming out of the boiler... and the process continues, this is the simplified theory of rectification. Of course, at some point, we need to collect the purified alcohol. And that's where these abbreviations come into play.

Let's start with a system that's not commonly found in packed columns, which is:

1. CM System: The letters CM stand for Cooling Management. Literally, it means "cooling regulation" - it involves having one upper condenser and one lower condenser. By regulating the water flow through the upper condenser, we divert some of the vapors to the lower condenser. Managing this system can be challenging as it requires either a large cooling capacity or extremely precise water flow regulation. Adjusting the water flow through the upper condenser affects how much vapor goes to the lower condenser. If you have a neighbor sharing the water supply or someone in your household decides to turn on a tap (or, heaven forbid, start a washing machine or dishwasher!), the whole process can be destabilized. That's why columns of the 'cold fingers' type, often mistakenly referred to as 'CF', are no longer professionally manufactured. The CM system is used only where a large cooling capacity ensures trouble-free operation, such as in shotgun-type condensers (multi-tube). In those cases, the CM system works very well because the large dimensions of these condensers allow for pressure surges in the system.

2. LM System: Similarly, the LM system stands for Liquid Management, regulating liquid flow. In the LM system, there's a condenser at the top of the column that condenses all the vapor, and the condensate falls onto two sloping shelves below the condenser. The shelves are arranged so that everything from the upper one falls onto the lower one, and from the lower one into the middle of the packing. The lower shelf has a valve. Between the column wall and the lower shelf, a pool of condensed liquid (called 'flegma') accumulates. By opening and closing the valve, we regulate the amount of liquid reaching the packing. Adjusting the valve allows us to control the reflux. The LM system can work with any variable water pressure (including a closed-loop system), making it the most versatile rectification system. Every column we offer comes equipped with this system. With LM, you can produce both pure 96% alcohol and various flavored distillates. The Terra column is a typical LM column.

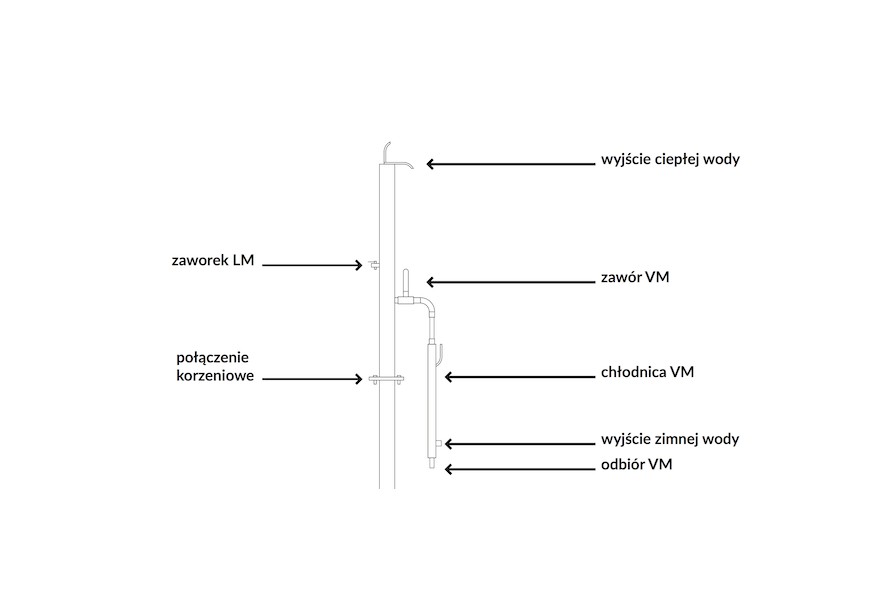

3. VM System: This acronym stands for Vapour Management, dividing vapor. It works slightly differently than LM. While the condensed liquid in the column behaves similarly, in VM, we 'take away' some of the vapor before it condenses. This is done with an additional, lateral condenser, attached to the column with a ball valve. Unlike in CM, the water circulation in VM doesn't need to be separated. Because the lateral VM condenser is always cooled, it's cooler than the column, creating a vacuum that sucks the vapors from the column into the condenser, where they condense. We regulate the amount of vapor taken by adjusting the ball valve, similar to LM. The VM system is only used to produce pure alcohol and cannot be used to produce flavored spirits. However, it yields well-purified and cold 96% alcohol. To collect the early fractions (sometimes colloquially referred to as the 'first 50'), we use the LM valve, and only after collecting the initial fractions do we open the VM valve. Every column we offer is equipped with the VM system from the Basic model upwards.

4. Lower Collection Systems - OVM and OLM: The names of these systems can be confusing because they are a combination of the Polish word for 'lower' (hence 'O') and the name of one of the systems mentioned above. So, OVM stands for Lower VM, and OLM stands for Lower LM. The essence of their operation is the same as in VM or LM, but instead of collecting vapor, we collect condensed liquid. The OVM system differs from the VM system in that the collection is not in the head but a few centimeters below. This creates a buffer space between the OVM outlet and the head, where light fractions accumulate throughout the process. Thanks to this, we take less contaminated vapors from below the head, collecting a clean and cold product of 96%+. This is the only system where, besides the VM valve, we can simultaneously use the LM valve. Throughout the process, we can adjust the LM valve to collect fractions accumulated in the buffer space. This allows for faster collection of the main run without a long stabilization period, and additionally, we eliminate impurities before the heads, which are separated at the beginning. Every column we offer is equipped with the OVM system, and from the Premium model upwards, it is the standard.

OLM, on the other hand, operates on the same principles as OVM, but instead of vapor collection, we collect condensed liquid. This system is more cumbersome because the collected product, in liquid form, is hot, which can be felt in the room. It also requires the installation of a second precise valve in the column, and to reduce unpleasant odors in the room, an OLM condenser is also needed.

I hope this simple explanation clarified the mysterious abbreviations. If something is still unclear, don't worry - each set comes with an instruction manual that explains the processes step by step. You don't need to know the definitions or principles of the above systems to operate the column. The processes for making spirit and flavored distillates are described separately, very accessibly and with photos. We have many customers who start this new hobby as seniors, and they are very satisfied with our instructions included in both the manual and the attached guide on yeast, mashes, washes, and recipes.